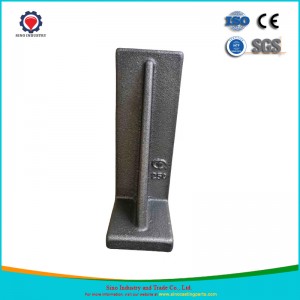

Casting Mechanical Parts with CNC Machining for Auto/Truck/Tractor/Forklift/Farm Vehicle/Train/Mining/Marine/Construction Machinery

Basic Info.

| Item | Ductile/Grey iron casting parts |

| Surface Preparation | Sand Blasting, Plating, Galvanized, Spray-Paint, Passivating, Polishing, Electrophoresis, Machining, etc. |

| Surface Treatment | Shot blasting/Polishing/Painting/Powder coating/Anodizing/Zinc plating/Nickel plating/blacking, etc. |

| Processing | Mold Making, Casting, Machining, Surface treatment, Inspection, Packing, Loading |

| Casting Blank Size | 2mm-1500mm or According to Customer's Requirement |

| Casting Blank Weight | 0.01kg-3000kg |

| Casting Method | Clay sand |

| Coated sand | |

| Silica sol casting | |

| Resin sand | |

| Lost Foam Casting | |

| Casting Standard | ISO ,DIN, AISI, ASTM, BS, JIS, etc. |

| Machining Method | CNC Machining, Milling, Drilling, Boring, etc |

| Design Software/ Formats | 3D, Auto CAD (IGS,DXF,DXF,DWG,STP, STEP,STL,X-T)/Soild Works, CAXA, Rhino, CATIA, SIMIO, ALIAS, ARENA, Unigraphics |

| Inspection Equipment | Spectrum Analyzer, Hexagon CMM, Hardness test equipment, Tension test machine, E-coating testing equipments, Metalloscope. |

| Dimension Inspection | Coordinate Measuring Machine (CMM),Calipers, Height Gauge, Micrometer Calipers, Inside Caliper Gauge, Angle and R Gauge,customized gauge, etc. |

| Application | Automobile, Car, Heavy Truck, Light Truck, Commercial Vehicle , Forklift, Construction Machinery/Truck/Vehicle, Farm Vehicle/Machinery/Truck, Agriculture Machinery/Truck/Vehicle, Mining Machinery, Marine Hardware, Train, Railway, Petroleum Machinery, Engineering Machinery, Shipbuilding, Power Equipment, etc. |

| Material | Grey iron,Ductile iron,Stainless steel, Carbon steel. |

| Weight | 0.1Kg-3Tons |

| Surface Roughness | Customized |

| Machining Tolerance | ±0.01mm |

| Standard | GB |

| Certification | ISO9001:2015, CE, SGS, RoHS, IATF16949 |

| Lead Time | 30-45 Days After Deposit |

| Service | OEM /ODM /OBM as Customers drawings or samples |

| Transport Package | Wooden Carton Pallet |

| Specification | customized size customers′ drawing |

| Trademark | Customized |

Product Description

Abrasion Resistant Slurry Pump for Gold Mining

Slurry Pump Equivalent with 12/10ST-AH Slurry pump

Max Flow: 550L/sec

Max Head: 68 Meters

Size: 1816x1510x1324mm

Weight: 4318kg

Suction: 12 inch

Discharge: 10 inch

Material: High chrome or Rubber liner

Slurry Pump Performance Parameters

| Type | Allowable Mating Max. Power(Kw) | Clear Water Performance | Impeller | |||||

| Capacity/Q m³/hr | Head/m | Speed/rpm | Max Efficiency/% | NPSH/m | Nos of Vane | Impeller Diameter/mm | ||

| 1.5X1-NP-AH | 15 | 12.6--28.8 | 6--68 | 1200--3800 | 40 | 2--4 | 5 | 152 |

| 2X1.5-NP-AH | 15 | 32.4--72 | 6--58 | 1200--3200 | 45 | 3.5--8 | 5 | 184 |

| 3X2-NP-AH | 30 | 39.6--86.4 | 12--64 | 1300--2700 | 55 | 4--6 | 5 | 214 |

| 4X3-NP-AH | 30 | 86.4--198 | 9--52 | 1000--2200 | 71 | 4--6 | 5 | 245 |

| 6X4-NP-AH | 60 | 162--360 | 12--56 | 800--1550 | 65 | 5--8 | 5 | 365 |

| 8X6-NP-AH | 300 | 360--828 | 10--61 | 500--1140 | 72 | 2--9 | 5 | 510 |

| 10X8-NP-AH | 560 | 612--1368 | 11--61 | 400--850 | 71 | 4--10 | 5 | 686 |

| 12X10-NP-AH | 560 | 936--1980 | 7--68 | 300--800 | 82 | 6 | 5 | 762 |

| 14X12-NP-AH | 560 | 1260--2772 | 13--63 | 300--600 | 77 | 3--10 | 5 | 965 |

| 16X14-NP-AH | 1200 | 1368--3060 | 11--63 | 250--550 | 79 | 4--10 | 5 | 1067 |

| 18X16-NP-AH | 1200 | 2520--5400 | 13--57 | 200--400 | 85 | 5--10 | 5 | 1370 |

Materials of Construction

| LINERS | IMPELLERS | CASING | BASE | EXPELLER | EXPELLER RING | SHAFT SLEEVE | SEALS | |

| Standard | Chrome Alloy Natural Rubber |

Chrome Alloy Natural Rubber |

SG Iron | SG Iron | Chrome Alloy or SG Iron |

Chrome Alloy or SG Iron |

SG Iron | Rubber and Nitrile |

| Options | Ferralium Hastelloy C 316 SS W151 Polyurethane Neoprene Butyl Viton Nitrile EPDM Hypalon |

Ferralium Hastelloy C 316 SS W151 Polyurethane Neoprene Butyl Nitrile Hypalon |

SG Iron Various grades |

MS Fabricated Cast Iron |

NI Resist Ferralium Hastelloy C Polyurethane 316 SS W151 |

NI Resist Ferralium Hastelloy C 316 SS Rubber W151 Polyurethane Neoprene Butyl Nitrile |

EN56C Ferralium Hastelloy C Titanium 316 SS 304 SS |

Ceramic Stellite Chrome Oxide Nordel Neoprene Viton |

Features

1. Centrifugal slurry pumps and spare parts can fully interchange with world famous brand.

2. These pumps are of heavy-duty construction, designed for continuous pumping of highly abrasive and corrosive slurries.

3. They feature a wide choice of replaceable abrasion resistant metal or moulded elastomer casting liners and Impellers, which are all interchangeable within a common casting assembly.

4. Wear -resistant Metal Liner and Rubber Liner available

5. Seal Type: gland Seal , Expeller Seal and Meachnical seal

6. Can be installed in multistage series

7. Can be positioned at intervals of 45 degree.

8. Easy to maintenance

Main castings

Machine components, machinery components, industry components, precision components, high performance components, device components, facility components, engine components, motor components, valve body, valve shell, valve casing, valve housing, gate valve, ball valve, connector, solenoid valve, pipe fittings, control valve, floating ball valve, pneumatic valve, industrial valve, gas valve, flange gate valve, directional valve, hydraulic control valve, butterfly valve, gearbox, gearbox components, gearbox body, gearbox shell, gearbox casing, gearbox housing, oil cylinder, water pump, impeller, pump impeller, stainless steel pump, centrifugal pump, slurry pump, sewage pump, electric pump, submersible pump, high pressure pump, chemical pump, pressure pump, water pump set, self-priming pump, garden pump, deep well pump, oil pump, fountain pump, pond pump, mud pump, single suction pump, fuel pump, hydraulic pump, hydraulic pump components, hydraulic spare components, pump spare components, water pump components, diesel pump, vacuum pump, pump components, pump body, pump shell, pump housing, pump casing, pump cover, auto pump, car pump, automotive pump, automobile pump, vehicle pump, truck pump, lorry pump, farm machinery components, farm machine components, farm vehicle components, farm truck components, agricultural machinery components, agriculture machinery components, agricultural machine components, agriculture machine components, agricultural vehicle components, agriculture vehicle components, agricultural truck components, agriculture truck components, combine harvester components, mining machinery components, mining machine components, mining truck components, mining vehicle components, mining equipment components, machine spare components, hardware components, marine hardware, petrochemical components, petrochemical machine components, petrochemical machinery components, petrochemical equipment components, petrochemical device components, petrochemical facility components, petrochemical installation components, petroleum components, petroleum machine components, petroleum machinery components, petroleum equipment components, petroleum device components, petroleum facility components, petroleum installation components, energy components, energy machine components, energy machinery components, energy equipment components, energy device components, energy facility components, energy installation components, power machine components, power machinery components, power equipment components, power device components, power facility components, power installation components, power plant components, power plant machine components, power plant machinery components, power plant equipment components, power plant device components, power plant facility components, power plant installation components, shipbuilding components, shipbuilding machine components, shipbuilding machinery components, shipbuilding equipment components, shipbuilding device components, shipbuilding facility components, shipbuilding installation components, engineering components, engineering machine components, engineering machinery components, engineering equipment components, engineering device components, engineering facility components, engineering installation components,high quality components, diesel engine, cast iron, iron casting, cast iron components, casting components, sand casting components, sand casting components, sand casting accessory, cast steel, steel casting, cast steel components, etc.

Application

Centrifugal mining slurry pump are widely used in mining, power, metallurgy, coal, deading, building material and other industrial lines to pump concentrate, tailings, sludge and other abrasive, high density slurries.

Minerals Flotation Processing

Electric Factory Coal Preparation

Coal Washing

Chemical Medium Processing

Effluent Handling

Sand And Gravel Handling

A professional OEM casing&CNC machining factory

We are professional casting and machining parts manufacturer in China. We can produce sand casting, precision casting, die casting and machining parts.

Our company can provide the most satisfactory OEM casting products according to customers' design drawings and detailed requirements.

It will be highly appreciated if you could send us detailed design drawings, specifications, quality requirements, or actual samples. We will provide you not only the most satisfactory processing service but also very competitive price, as well as fast delivery.

Our Service

1. Quick Reply

Your inquiry related to our products or prices will be replied within 12 hours.

2.Pump Choice .

Please let us know the application, capacity and head ,We can help to select the suitable pump

3.Technical Surport .

We have a group of high quality technicians with rich experience who can solve everything during the whole process.

4.Guarantee of quality.

All the products have proved by ISO 9001:2008, CE, SGS. And also will be inspected strictly before delivery. For Comon parts(except wet end parts,) waranty time: 1 years

5.OEM/ODM service.

We are a source manufacturer, and we have a complete production line, all production links from raw materials to finished products are under our control. We have special technology and skill to solve and handle special material, special structure, special defect and special processing. We can produce all kinds of castings with high precision CNC machining according to customer's drawings/samples/requirements.

FAQ

1. How can I get a quotation from your company?

Please send us information for quote: drawing, material, weight, quantity and request.

2. If i don't have a drawing, can you make drawing for me?

Yes, we make the drawing based on your sample and duplicate the sample.

3. When can I get the sample?

Approximately 25-30 days after you start to make mold.

4. What is the lead time?

Normally 30-45 days after deposit for mass production.

5. What is your payment terms?

30% by T/T in advance and balance before shipment.

6. For the drawings, which kind of file format can you accept?

PDF, ISGS, DWG, STEP, MAX…

7. If you export to our country before, can I get the information of your import customer in our country?

We can provide you with B/L of past shipments.

8. Are you a Trading Company or a Manufacturing Factory?

We are one professional OEM/ODM casting/machining factory, carrying out ISO9001 and IATF16949 quality management system, guarantee of quality. Our factory is located in Rizhao City, Shandong Province, P.R. China, it covers an area of more than 600000 square meters. And its only one and a half hours’ drive from our factory to the nearest shipping port-which makes our delivery system more efficient.

9. How can you guarantee the product quality?

We have passed the “ISO 9001” and “ IATF 16949” International Quality Management System Certification. We also have the professional QC team, and each our package worker will be in charge of the final inspection according to the QC instruction before packing.

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have a full inspection and routing inspection during mass production---In-process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)